Project Description

Key information

Project in the Spotlight: Perspectief programme AiM2XL

Market: Additive Manufacturing

Written by M2i Program Manager: Viktoria Savran

We are thrilled to share an exhilarating recap of the Perspectief programme AiM2XL, which took the spotlight at the 2023 TEKNOWLOGY festival organized by the Netherlands Organization for Scientific Research (NWO). As we entered the final year of AiM2XL programme, we can proudly reflect on the significant accomplishments and transformative outcomes achieved by the consortium.

At its core, AiM2XL, or Additive Manufacturing for Extra Large Metal Components, has been a collaborative endeavour between four leading Dutch universities— Delft University of Technology, Eindhoven University of Technology, Twente University and University of Groningen — alongside 17 esteemed industrial companies (Air Liquide B.V., Allseas, Autodesk, Damen, Element Materials Technology, Fokker Technologies Holding B.V., Heerema Fabrication Group, Huisman, Jungle, Lincoln Electric B.V., Lloyd’s Register EMEA, MX3D, OCAS NV, Shell, Trumpf Nederland B.V., Valk Welding B.V. and VandeGrijp International Gear Suppliers B.V.), the network organization M2i and the field lab RAMLAB. With generous funding from NWO since 2017, the consortium embarked on an exciting journey to explore metal-based additive manufacturing technologies, with a primary focus on the Wire Arc Welding process.

While Wire Arc Welding has been known for almost a century as a welding technique, until recently it was limited to only joining metal products. The emergence of additive manufacturing, also known as 3D printing, presented an opportunity to leverage this well-established technique to produce large-scale 3D metal objects. When AiM2XL was initiated 7 years ago, most 3D printing technologies were only capable of producing relatively small-sized products, ranging from a few centimetres to maximum a half meter. Back then there were no solutions to produce large, meter-scale metal products. That gave us the idea to use welding robots and to reprogram these for 3D printing of large metal objects.

Despite early scepticism from some academic and industrial partners, who questioned the feasibility of printing large-scale metal objects with wire arc welding robots due to concerns about welding defects and product quality, NWO recognized the untapped potential of AiM2XL and provided the grant. This pivotal support allowed the consortium to push the boundaries of wire-arc additive manufacturing (WAAM) and to embark on an exciting journey of discovery and innovation.

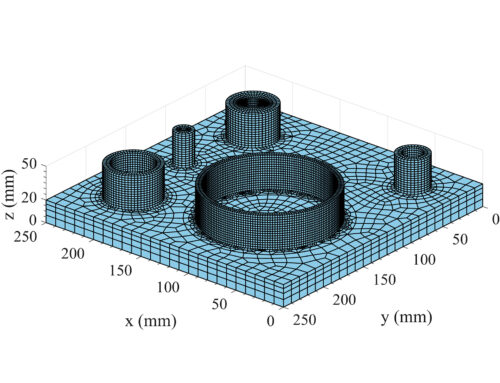

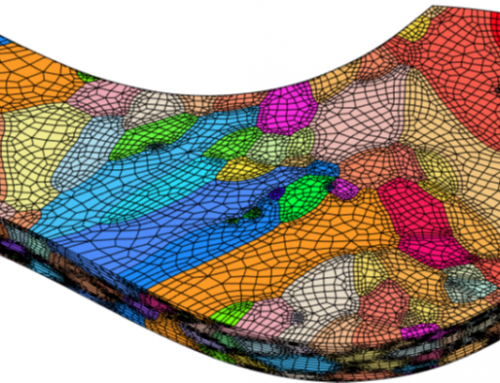

The uniqueness of the AiM2XL program lies in its materials-centric approach. Recognizing the significance of mechanical properties in manufactured products, the consortium aimed to bridge the gap between “process parameters” and “properties” by focusing on understanding microstructure formation — a critical factor influencing the final product properties. Over the course of five years, the consortium achieved significant progress in unravelling the complexities of microstructure formation during the 3D printing process. The team developed highly accurate models for predicting microstructures in steel products, paving the way for precise control over material properties during 3D printing.

One of the standout achievements of AiM2XL has been the development of a topology optimization algorithm. Leveraging the freedom of depositing material in desired locations, this algorithm enables optimal production of complex-shaped products while simultaneously achieving significant weight reduction — a capability not available in traditional manufacturing methods such as casting, forging or machining.

To demonstrate the transformative potential of the research, AiM2XL findings were tested on three demonstrators, with increasing level of size and complexity: a lifting lug, which was showcased at the Demo Market of TEKNOWLOGY, a fork and a ship rudder. The first demonstrator, the lifting lug, is a critical structural component used in maritime and aerospace applications to lift large heavy objects. It was successfully manufactured by RAMLAB using WAAM. The second demonstrator, the fork, highlights the achievable increased size and was used to test different deposition strategies. Lastly, and most impressively, a ship rudder — an underwater blade for steering ships — was redesigned using the topology optimization algorithm. This innovative redesign resulted in a nearly 30% reduction in weight (approx. 200 kg) without compromising on its properties, leading to improved resource efficiency, reduced fuel consumption and lowered CO2 emissions during the operation of the ship.

The success of the AiM2XL program can be attributed to the exceptional collaboration and dedication of the individuals involved. The consortium acknowledges the visionary leadership of Bert van Haastrecht (M2i), Vincent Wegener (RAMLAB), Ian Richardson and Fred van Keulen (TU Delft), whose passion and belief in the potential of WAAM have been instrumental in driving this program forward. Moreover, the active involvement of the industrial partners ensured that the knowledge generated within AiM2XL is not only relevant but also applicable in real-world industrial practices.

Looking ahead, AiM2XL is not resting on its laurels. The consortium is already setting its sights on new horizons, embarking on the Grade2XL project (also initiated and coordinated by M2i) — an ambitious undertaking that received €10 million funding from the European Commission. This new initiative aims to enable multi-material 3D printing using WAAM, further expanding the realm of possibilities. Additionally, AiM2XL sees immense potential in the fields of remanufacturing and repair applications, with plans to collaborate with TU Delft on a future Perspective program.

If you are intrigued by the achievements of AiM2XL and would like to explore the possibilities of large-scale metal component manufacturing, we invite you to connect with us.

Let’s revolutionize the future together!