Project Description

Key information

Project in the Spotlight: T22002

Market: Chemical technology

Written by M2i Program Manager: Yulia Fischer

Tunable Cell-Adhesive Surfaces

One of the most pressing needs in materials science concerns the increased longevity of tailor-made devices, so as to decrease both use of materials and costs. An interesting challenge in the field of cell assays is to create surfaces that promote cell adhesion without introduction of cell stress. At the same time, to enable re-use and to allow collection of cells for downstream assays one would like to have an easy and gentle method for cell removal and surface regeneration. Currently this is not feasible, as most surfaces for cell immobilization require harsh chemicals for cell removal and are difficult to fully clean and bring back to their original state. The aims of the project was to develop switchable surfaces and to design new, simple and sustainable strategies for creating smart cell interactive surfaces for cancer research together with the project partner LUMICKS B.V.

LUMICKS develops methods and instruments to measure cell avidity, the binding strength between cells which involves many interactions between cells and surfaces and with other cells. Cell avidity plays a crucial role in immune response and many other biological processes. The ability to measure cell avidity can greatly improve cancer treatment, tissue engineering, etc. Current methods use tailor-made, expensive, reusable chips or surfaces. The subsequent cleaning protocol of such biochip and biointeractive surfaces often requires repeated etching, leading to device damage. It is, therefore, advantageous to pursue coating methods that allow tunable and switchable cell adhesion.

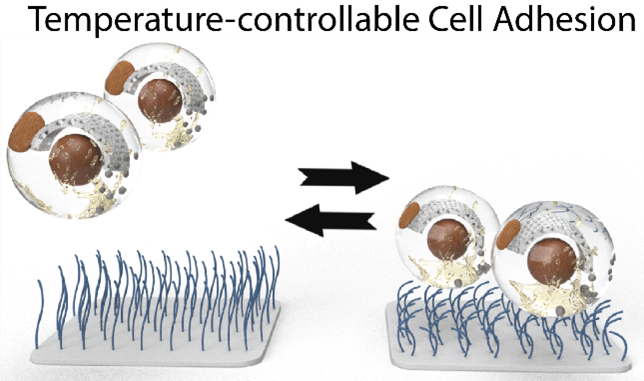

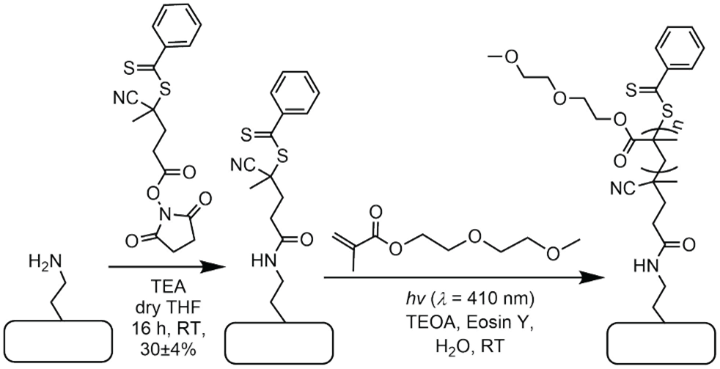

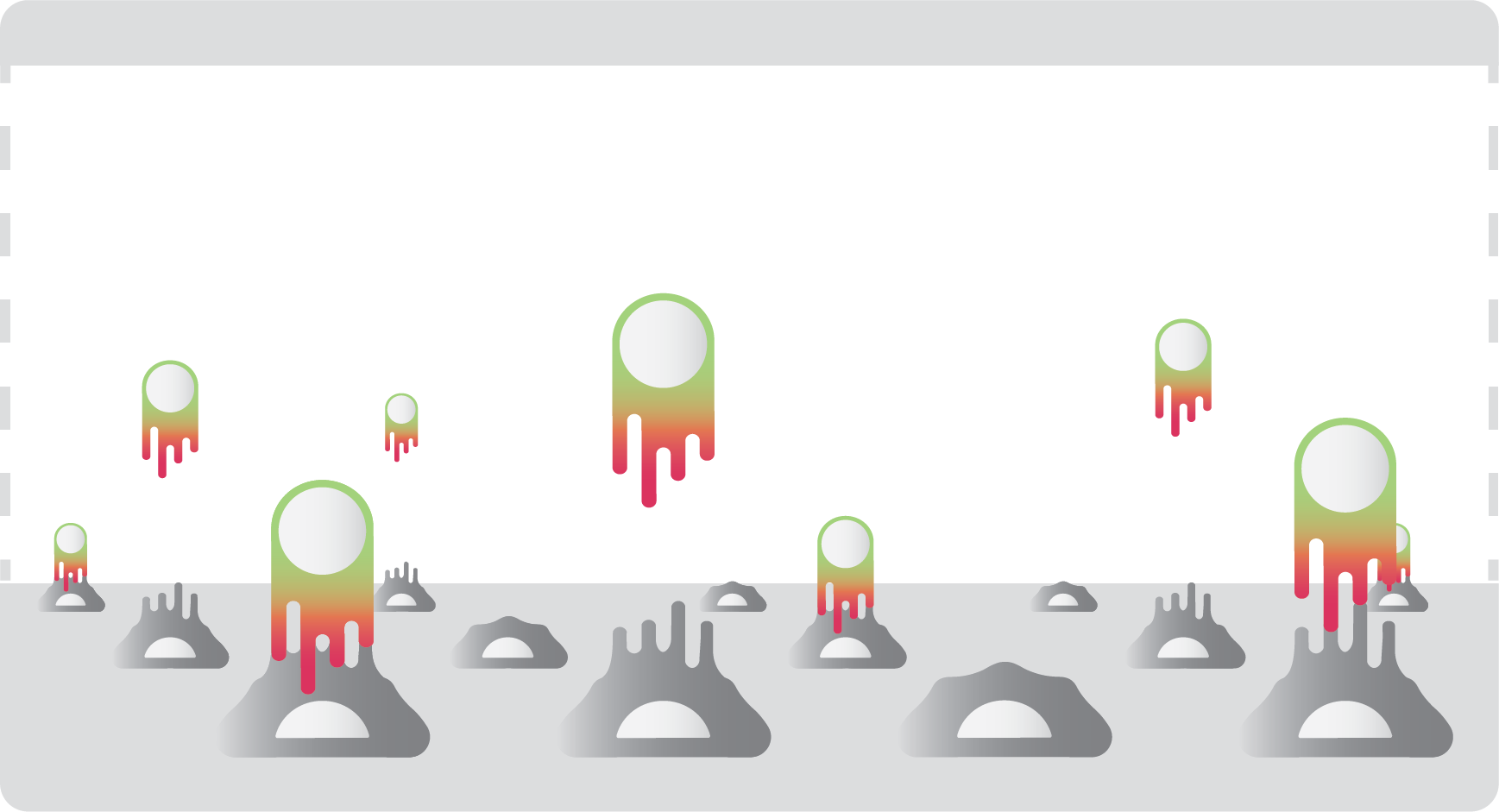

To tackle this issue, postdoctoral researcher Andriy Kuzmyn , working in the group of Prof. Han Zuilhof at Wageningen University and Research, developed temperature-switchable poly(di(ethylene glycol) methyl ether methacrylate) brush-based cell-interactive coatings produced by surface-initiated photoinduced electron transfer reversible addition-fragmentation chain transfer polymerization (SI-PET-RAFT). This technique allows a simple and mass-manufactured approach to the creation of polymer brushes. The temperature switch of brushes was investigated by quartz crystal microbalance with dissipation monitoring (QCM-D), chemical composition, and physicochemical properties by atom force microscopy (AFM), X-ray photoelectron spectroscopy (XPS), single-molecule force spectroscopy (SMFS), and ellipsometry. The temperature of the switch of poly(MeOMA) brushes was tuned to occur at 23 °C such that cell avidity experiments could be performed at 37 °C and cell release could be induced by simple cooling of the devices. The brush coatings showed good stability and thermal switchability for 100 cycles of heating and cooling. Moreover, the temperature triggered adhesion and release of Nalm6 cells on poly(MeOMA) coatings were confirmed by bright-field microscopy.

To tackle this issue, postdoctoral researcher Andriy Kuzmyn , working in the group of Prof. Han Zuilhof at Wageningen University and Research, developed temperature-switchable poly(di(ethylene glycol) methyl ether methacrylate) brush-based cell-interactive coatings produced by surface-initiated photoinduced electron transfer reversible addition-fragmentation chain transfer polymerization (SI-PET-RAFT). This technique allows a simple and mass-manufactured approach to the creation of polymer brushes. The temperature switch of brushes was investigated by quartz crystal microbalance with dissipation monitoring (QCM-D), chemical composition, and physicochemical properties by atom force microscopy (AFM), X-ray photoelectron spectroscopy (XPS), single-molecule force spectroscopy (SMFS), and ellipsometry. The temperature of the switch of poly(MeOMA) brushes was tuned to occur at 23 °C such that cell avidity experiments could be performed at 37 °C and cell release could be induced by simple cooling of the devices. The brush coatings showed good stability and thermal switchability for 100 cycles of heating and cooling. Moreover, the temperature triggered adhesion and release of Nalm6 cells on poly(MeOMA) coatings were confirmed by bright-field microscopy.

The switchable coatings and methods developed during this project may be used in the next generation of LUMICKS devices to enable programmable cell release. This can help to accelerate the development of new immune therapies for cancer and other diseases.