Project Description

Key information

Project in the Spotlight: A21017a

Market: Packaging

Researcher: Ilhan Ilknur

Written by M2i Program Manager: Yulia Fischer

Introduction

This research project is part of a wider Topsector Agri & Food project named “Innovative Smart Materials and Sensors for Packaging of Raw and Processed Food Products”. It is a multidisciplinary project that covers improved packaging materials, better sealing applications, and better packaging sensors that allow monitoring of food quality. After getting Privaat-Publieke Samenwerking (PPS) in 2018, this part of the research focusing on detecting and eliminating the causes of seal leakages in flexible packaging started in 2019 at the University of Twente.

According to United Nations Environment Programme (UNEP) Food Waste Index Report 2021, 17% of produced total global food (931 million tonnes) became food waste in 2019 and 13% of this food waste was coming from retail. According to an estimation, 8% of the food packaging might not provide the required protection through the supply chain due to difficul to detect small seal leakages in the seal area. Therefore, eliminating seal leakages can have a significant role in food waste prevention as well as reducing the number of consumer complaints.

Problem statement

Protecting the food item from undesired chemical and biological changes is one of the major functions of food packaging. The seal area has a key role to preserve this function and to achieve packaging requirements such as maintaining modified atmosphere gas composition. Often packaging with high seal strength is assumed having also good seal integrity. However, high seal strength does not guarantee to achieve full seal integrity or hermetic packaging. Seal integrity studies show that small channels in the seal interface allow gas and moisture ingress that can cause detrimental changes to the quality of sensitive products throughout their shelf life. Moreover, pathogens can diffuse into the package through small channels less than 5 μm and pose a risk to food safety.

Although, using large seal areas and thicker sealant layers, applying higher sealing times and temperatures can eliminate seal integrity issues, these methods increase packaging material and energy consumption. Thus, both from a circularity and food quality perspective, it is evident that we need to develop a better understanding of heat sealing and leak formation mechanisms.

Another problem is enhancing peelability function without causing leakage at the seal area. Peelability function is desired for most of the packaging for easy access to the content and consumer friendliness. However, in some cases, easy opening means weakly bonded seals that can easily be damaged during handling.

To cover all these problems, the main questions of the research are formulated as “What is happening at the interphase of two sealant materials that cause leakages if you combine them by applying heat for closing?” and “How can the peelability function and process efficiency be enhanced without causing leakage at the seal area?”.

Project vision

The main objectives of this project are to reveal the reasons behind encountered seal integrity problems in the heat sealing of flexible food packaging, develop and demonstrate strategies and methods for coping with seal integrity issues that cause food waste and economic damage, and minimize failures while achieving packaging requirements. It first aims to understand the reasons behind the leak formation during and after the sealing process and then tries to develop suggestions towards minimizing seal integrity problems. At the same time, it tries to find ways to cope with the complexity of various material characteristics and changing process parameters and packaging requirements such as easy peeling.

Thus, the vision of success of this research is ultimately, reducing food waste, excess material use, energy use, and increasing consumer friendliness via optimizing the parameters having a role in seal integrity and seal strength development.

Main achievements

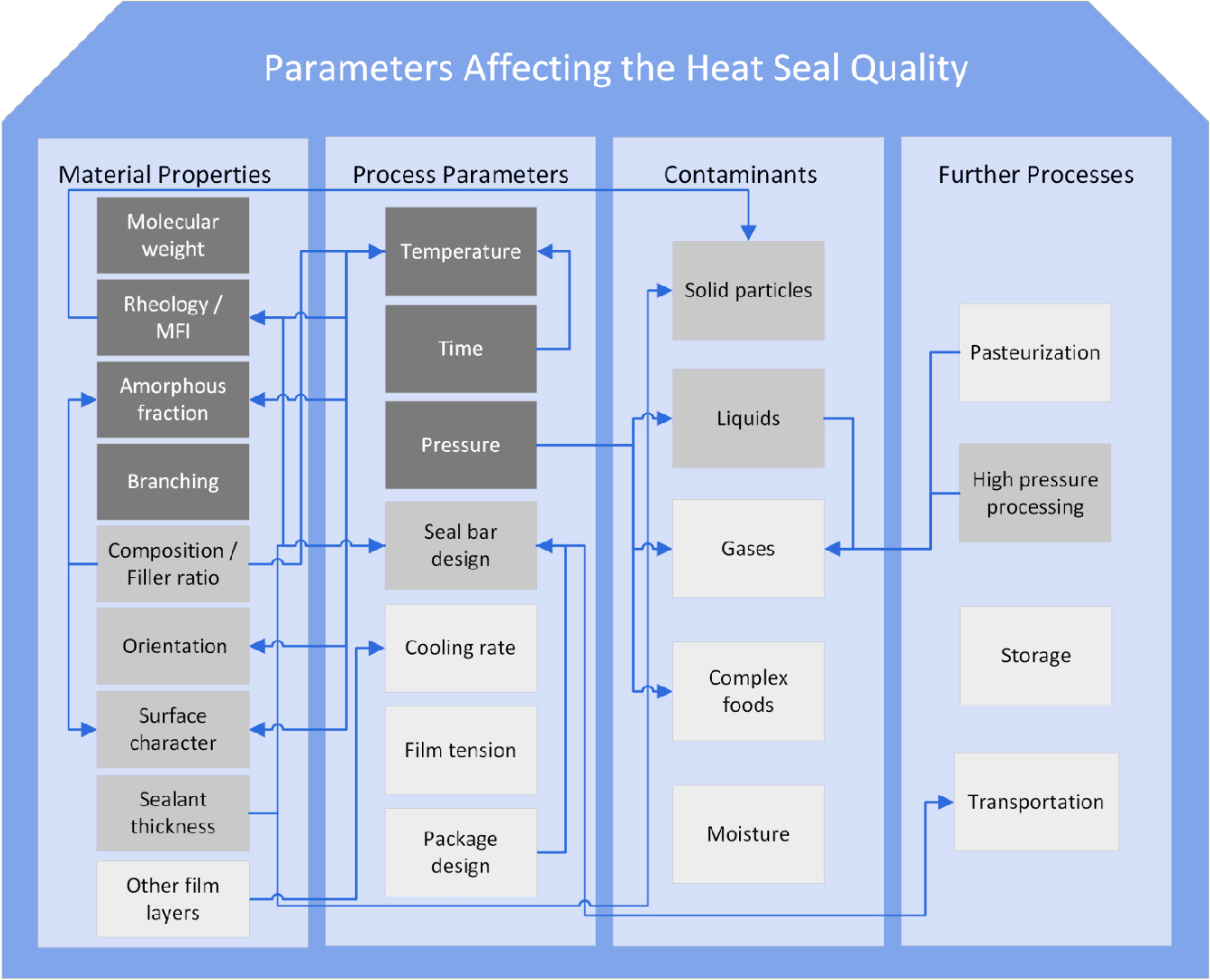

The project mapped out many different parameters, grouped as material properties, process parameters, contaminants and future processes, related to the formation of gaps and micro-leakages in the seal area (given in Figure 1). Among these intrinsically linked parameters, some focus parameters such as film tension, contamination, MFI, seal bar design and filler ratio are chosen and researched further to show their influences on the seal quality.

Through experimental research it has been shown that:

- The level of allowable solid food particle contamination density in the seal area changes based on particle size and it is lower for finer food particles. Therefore, sealing time and temperature should be adjusted considering the amount and size of contaminant particles.

- Seal bar design can directly influence seal strength and seal integrity, thus further tuning of seal bar design to optimize pressure distribution along the seal such as top and bottom seal is necessary.

- Pressure fluctuations occur based on the layer jumps along the seal, and package design has a great impact on seal quality and leak formation.

- The composition of film and sealant material is strongly linked to optimum sealing temperature and dwell time, and both required to be optimized based on diffusion distance to increase process efficiency.

- By modifying the main process parameters, melt behavior, filler ratio and film tension and/or changing the package design it is possible to strongly reduce micro-leakages.

- Easy peal function can be achieved by avoiding excessive pressure and film tension along with precise optimization of sealing time and temperature.

Involved partners

Research institutes

Research is conducted at the University of Twente: Engineering Technology / Packaging Design and Management Chair

Other research institutes involved in the consortium

- Eindhoven University of Technology

- Delft University of Technology

- Wageningen University

- Wageningen Food & Biobased Research

- Eindhoven University of Technology

Involved (end)users

Companies: Yparex, Oerlemans Plastics, JDE, Trivium Packaging, Heineken, Avery Dennison, Koninklijke Peijnenburg

Other organizations

Materials innovation institute, M2i

Researcher

Ilknur Ilhan successfully defended her PhD thesis on 13th of July 2023 at University of Twente. Link to the digital copy of the thesis is here. The work of Ilhan is a significant contribution to the research for sustainable future of the packaging industry and she received an assistant professor position at University of Twente.