Project Description

Key information

Project in the Spotlight: T16045 (INTERMOD)

Market: Civil

Written by: Viktoria Savran

A multi-scale approach towards reusable steel-concrete composite floor systems (INTERMOD)

Sustainability is becoming increasingly important in the construction sector. Demountable and reusable structures are one way to extend the exploitation life of buildings and to provide solutions for a more resource efficient and CO2 neutral industry. Within the INTERMOD project (T16045) Martin Nijgh, under supervision of prof. Milan Veljkovic from Delft University of Technology, worked together with Bouwen met Staal and SNS Intra to provide a scientific background for a technical solution to enable the easy demountability and subsequent reusability of steel-concrete composite floor systems. The research was undertaken in the global framework of the transition from a linear to a circular construction sector, where priority is given to reuse of structures (or structural components). The key innovation is in connecting the concrete deck and steel girders with oversized holes (6 times larger clearance then allowed according to existing rules) in steel beams. This requires a scientifically based and technically integrated solution that enables the easy reusability of the composite floor system whilst optimising the material efficiency of the structural components.

Project objectives and outcomes

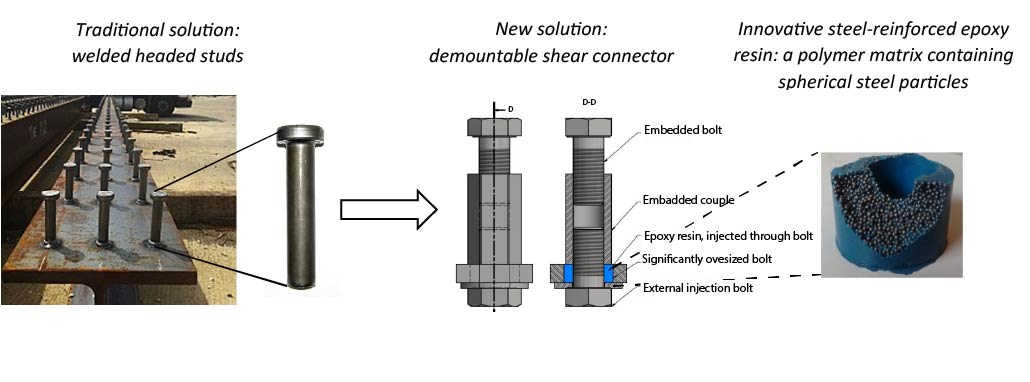

The first objective of INTERMOD research project was to develop a demountable shear connector by combining commercially available products, accomplishing a product close to the market. The innovation facilitates the rapid and easy (dis)assembly of the composite floor systems consisting of prefabricated elements. In essence, the newly developed product solves the shortcomings of welded headed studs traditionally used in composite floor systems (see Figure).

The second objective was to experimentally establish the material behaviour of the demountable shear connectors constituents. This part of research challenge mainly focused on the behaviour of load-bearing (steel-reinforced) epoxy resin injectants which is the most important component for the use of larger hole clearances and enables instantaneous composite interaction despite these clearances. The goal was to gain knowledge about short-term and long-term material properties of the injectants. This information is crucial for predicting the mechanical behaviour of injected bolted connections by FEM.

The third objective was to obtain the short-term and long-term relation between applied load and deformation (slip) of the proposed demountable shear connector. The prediction of the long-term behaviour of injected bolted steel-to-steel connections was made and validated against experimental push-out and double-lap (steel-to-steel) shear connection tests. The study was followed by an extensive parameter study to derive design recommendations for the demountable shear connector for its short-term response. The overall goal of the objective was to provide structural shear connector characteristics that can be used to predict the mechanical behaviour of demountable and reusable composite floor systems.

The fourth and final objective was to investigate the feasibility of construction and structural response of a demountable composite floor system. It was done on a full scale model of a segment of a car-park executed in the TUD laboratory, Stevin 2. The research distinguished itself through the focus on non-prismatic steel beams and a non-uniform distribution of shear connectors to optimise the elastic structural response. The feasibility of construction was addressed experimentally and analytically by proposing a prediction methodology to quantify the minimum nominal hole clearances required for successful assembly and disassembly. The experimental results were used to validate analytical prediction models for the load-deflection and load-slip response for the composite floor system. Additional models were developed to analyse instability during execution and the first (fundamental) eigenfrequency during the use-phase. The overall goal of the objective was to enable implementation of demountable and reusable composite floor systems in engineering and construction practice.

The project T16045 INTERMOD got PPS funding in 2018-2021

Prof. Milan Veljkovic (TU Delft)

Impact of the INTERMOD research project will certainly be large in the years to come. Based on the outcomes we have defined several research and application areas, in particular:

- Ministry of Infrastructure and Water management (RWS) has become interested in using reinforce resin in combination of steel beams with FRP deck in movable bridges.

- Consortium of several Dutch industrial companies was established to prepare a proposal for Circular Viaducts.

- A new proposal is in a preparation phase for Innovatie & Ontwikkeling Programma Bruggen & Kademuren, Gemeente Amsterdam. The proposal for the renovation and new bridges over channels in Amsterdam may be an attractive application because of the flexibility and speed in renovation. Competitive solution could be accomplished based on the knowledge of oversized holes injected by reinforced resin developed in INTERMOD project.

Nico Noorlander (Director SNS Intra)

Nico Noorlander (Director SNS Intra)

From this research project it became evident that significant gains in terms of sustainability can be obtained in the conservative field of steel-concrete composite floor systems. Creating a modular construction system that can be easily demounted for reuse in another application is what we need in order to develop a sustainable world. What is also important for us is that the advantages of demountable and reusable structures are not limited to environmental aspects only, but also include simplified maintenance procedures, increased adaptability, reduced costs and hindrance during disassembly compared to demolition, and reduced financial risks because the building can be repurposed.

Frank Maatje (Director Bouwen met Staal)

Frank Maatje (Director Bouwen met Staal)

The results of INTERMOD project brings us closer to the circular design solutions in a construction industry that are much needed. INTERMOD helped us to understand better the three levels of system complexity (injectant, connector, and floor system) relevant to demountable and reusable steel-concrete floor systems. Guidance on demountable composite construction systems is now under development.