Project Description

Key information

Project in the Spotlight: S17013a/16347

Market: Civil

Written by Kinga Klima and M2i Program Manager: Viktoria Savran

Introduction

Today great attention is paid to the increased energy efficiency in buildings. This has resulted in the application of many new synthetic materials for thermal insulation. Often these synthetic materials suffer from low fire resistance. Moreover, most materials and structures rapidly lose mechanical strength at elevated temperatures, resulting in damage which can restrict evacuation and rescue operations. It’s also a great problem that synthetic materials produce a lot of smoke, which is life-threatening for the people inside a building and which creates a lot of inconvenience for the surrounding objects. Besides, most structural materials like steel, Portland cement and plastics are highly energy-intensive materials and great amounts of CO2 are emitted during their life cycle. This project aims to develop engineered inorganic geopolymeric binders that can be used in low-CO2 and functional fire-protective coatings, or as a binder in concrete elements to overcome the disadvantages associated with current structural materials. Geopolymeric binders, as an alternative to traditional Portland cement, have the potential to meet contemporary functional requirements concerning high sustainability and intrinsic excellent thermal and fire resistance. However, many unsolved issues still exist, such as the deleterious effects caused by certain types of secondary phases, and the precursors and activators used still need further optimization.

Project goal and outcomes

At the beginning of the project, the main objective was to design a fire-resistant material. During the design process, it was concluded that the protective material in the form of boards would be more beneficial in fire safety terms rather than as a structural element. The porous composite and its properties at room temperature as a thermal and acoustic insulator, as well as at high temperatures up to 1100 °C, were designed to achieve the majority of the initial research goals. Another approach to improve material porosity and reinforce the structure by incorporating a zeolitic filler was proposed. An additional effort was made to propose an alternative utilisation route for mineral wool waste as a solid precursor for the manufacture of artificial aggregate. An artificial aggregate based on the mineral wool waste that may be utilised as an alternative to currently used natural aggregates in various types of concrete. The optimum curing regime has been proposed, and the room and high-temperature performance of the designed artificial aggregate were tested. When used in geopolymers for high temperatures, they exhibit better microstructural stability and mechanical performance than regular sand.

The research was carried out by a combination of laboratory and full-scale experiments and theoretical modelling, among others in close cooperation with Fire Brigade Netherlands (Brandweer Nederland), Tata Steel, and Rockwool. The project provided the material producers with information on the products’ performance under different fire exposure conditions, which is now lacking. The smart utilization of industrial by-products and waste materials in aforesaid high-end fire-resistant coating and structural elements enables the upgrading of waste materials and industrial by-products. Moreover, the research provides the fire brigades with missing information on the fire behaviour in modern buildings equipped with various composite materials and will enable them to further introduce new fire safety doctrines and the choice of appropriate intervention strategies.

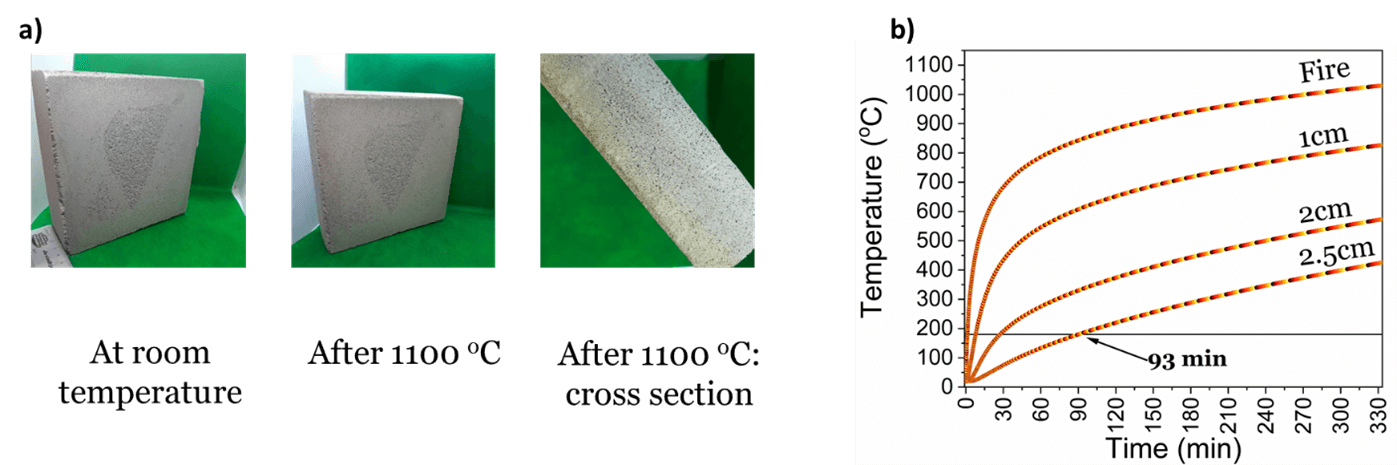

The most notable findings are connected to both microstructure alteration and the geopolymer enrichment approach. A suitable mixture of two surfactants can be used to control the total pore volume, open porosity and pore size distribution. In turn, this differentiated pore structure has a significant impact on the material’s high-temperature response, as a higher proportion of open pores reduces the risk of thermal stress and cracking. Taking into account the ISO 834 fire scenario, a 2.5 cm thick panel designed in this manner can be a protective barrier (Fig.1), for example, for concrete for 93 minutes (before it reaches the temperature of 180 oC).

The use of synthetic zeolite or artificial aggregates to reinforce the matrix has also been suggested as a good technique for reducing the negative impact of high temperature on the material’s response, i.e. shrinkage and material deformation. Zeolite addition at 5 wt% significantly improves the thermal properties of geopolymers. In the case of artificial aggregates, the results confirm the validity of the proposed waste utilization method and may direct future research to further optimization of the aggregates production method. Noteworthy, in terms of strength development at room and after high-temperature exposure (1100 oC), the two types of artificial aggregates manufactured outperform commonly used sand in the geopolymer matrix.

Figure 1. Designed porous geopolymer a) the visual evaluation before and after exposure to 1100 oC;

b) temperature response of the material when exposed to ISO834 fire scenario.

Project S17013a got NWO-TTW funding (16347) in 2018-2022. Kinga Klima worked in the group of prof. Jos Brouwers, co-supervised by Dr. Qingliang Yu, and in close collaboration with Anna Monika Kaja and Miruna Florea. Industrial companies Brandweer Nederland, Van Gansewinkel Minerals, Rockwool, Nieman, Kijlstra Beton and Tata Steel, next to financial support, supported the project with materials and testing at industrial environment.

| Kinga Klima (TU Eindhoven) |

|---|

|

It was an incredible experience to be in the role of a researcher in a project that is both important for the world of science and society. When designing new buildings or renovating existing ones, fire safety and passive protection of both public buildings and private single-family houses should be prioritised. As a result, this project emphasises the importance of strengthening fire safety requirements in Europe and focuses on new, more sustainable protective materials in the construction industry. I believe that the strategic use of waste materials and industrial by-products in the development of high-temperature resistant products can inspire and provide waste material players with a new strategy to deal with and upgrade waste streams and industrial by-products.

The fire service of the Netherlands aims to be more involved in innovation and research in order to improve the fire safety of society. Therefore we were happy to be able to contribute to this innovative research. Developing non-combustible insulation materials could improve fire safety, especially if made of waste products, which would be circular and sustainable. This study contributes to the aims of the fire service and the FRS (Fire and Rescue Service) is very happy that it showed to be possible to really make this insulation material from geopolymer and waste products. This is a big step towards both fire safety and a sustainable society.