Project Description

Key Information

- EU funding: € 2.35 Million

- Total budget: € 4.74 Million

- Duration: 63 months [May 2016 – August 2021]

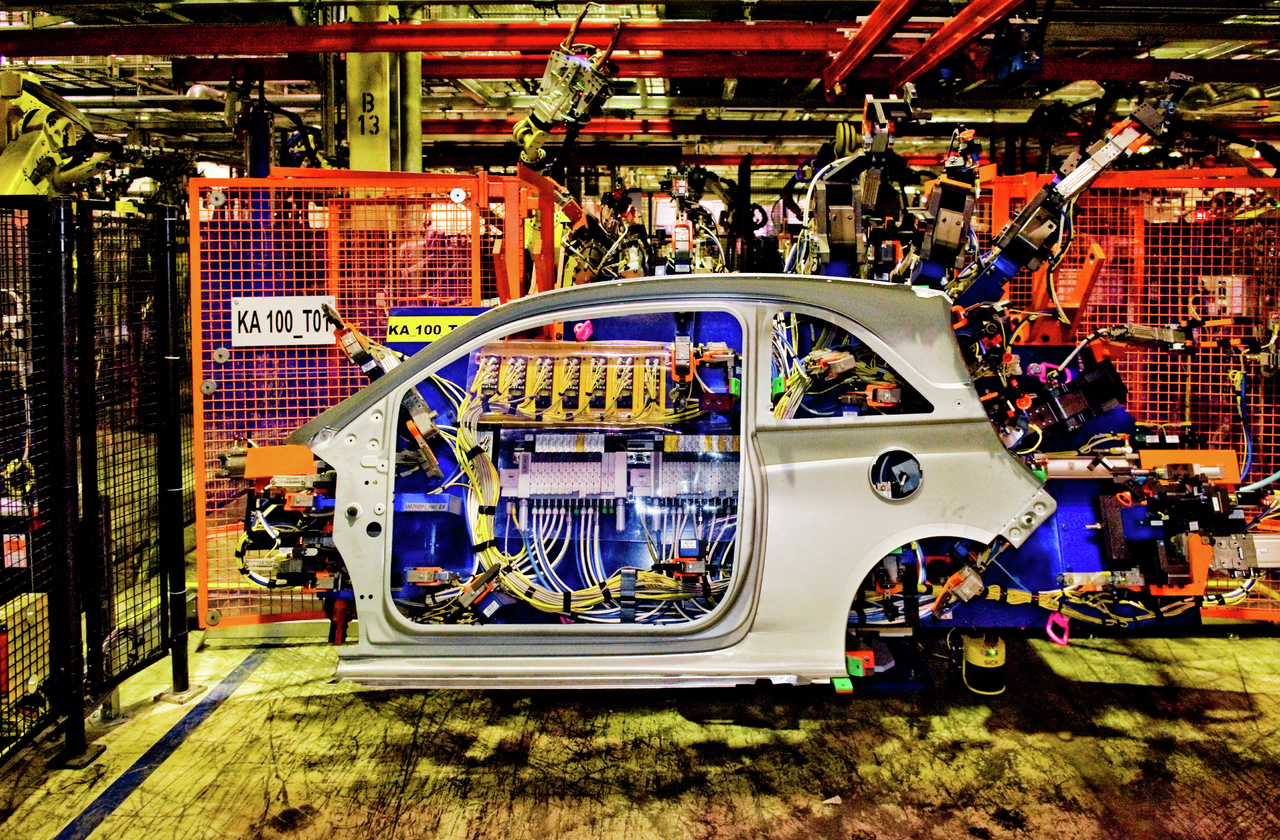

Background: The design of sheet metal forming processes is nowadays done virtually, i.e. by computer simulations. A limitation in these simulations is the assumption of a constant friction value over the course of the process, while in reality a temperature increase of 40°C in the tool – during the start-up of the production line – impacts on the tribology between the tool and sheet material, leading to a friction increase of up to 25 % and product failures as a result. The control of these effects is currently done reactively, by trial-and-error approaches, based on the individual experience of the machine operators, rather than by using automated, adaptive control systems. The current practice therefore results in process instability, high costs and slow process development. Moreover, with the increasing use of advanced steel grades, which generate more heat purely due to their strength, predicting and controlling the influence of temperature on friction becomes critical for the concerned industries.

The ASPECT project, funded by the programme INTERREG North-West Europe, aims to create a robust framework to predict friction increase with temperature and to develop a control system that can instantaneously correct the applied forces to account for the sensed friction increase.

M2i is leading the ASPECT consortium and has been carrying out the following tasks:

- (WP P) Project initiation: proposal coordination and writing, consortium building

- (WP M) Project management and contact point with the funding organisation

- (WP T.1) Implementing methods to achieve faster thermo-coupled FE simulations

- (WP C) Survey to identify research and industry organization interested in ASPECT results

- (WP LT) Promoting actions to support diffusion of project results towards target groups

Project Partners:

- Stichting Materials Innovation Institute (M2i), The Netherlands – Lead Partner

- Triboform Engineering BV, The Netherlands

- ESI GROUP, France

- Falex Tribology NV, Belgium

- Universiteit Twente, The Netherlands

- Zeller+Gmelin GmbH, Germany

- Tata Steel Nederland Technology BV, The Netherlands

- INSPIRE AG, Switzerland

- Opel Automobile GmbH, Germany

- Philips Consumer Lifestyle BV, The Netherlands

- AutomotiveNL, The Netherlands

- Pôle EMC2, France

- Dr. FILZEK TRIBOtech, Germany

- ESI Software GmbH, Germany

Expected results:

- Numerical model to predict friction variation based on real process conditions;

- Fully-automated forming demonstrators for Automotive and Consumer goods applications;

- Joint demonstration facility, open for training and education;

- Guidelines to improve the material, tool and lubricant design.

For more information please visit ASPECT webpage at: www.nweurope.eu/aspect

News

Looking back at a successful Final ASPECT Event

Last week, on 15 June 2021, the Final ASPECT Event took place as an online event. The ASPECT project ran for five years and was funded from the INTERREG North-West

Teaser ASPECT; Register now for the Final event

On 15 June 2021, the final event of the INTERREG project ASPECT will mark the end of the project. Watch the teaser and register for the event.

Practical Training “Temperature-induced friction influence in sheet metal forming processes”

We are happy to invite you to a Practical Training in ‘temperature-induced friction influence in sheet metal forming processes’, which will take place on the 18th of June 2021 online

Register now for the ASPECT Final event

On 15 June 2021, the final event of the INTERREG project ASPECT will mark the end of the project. ASPECT has enabled the prediction and control of temperature-induced effects on

Final event ASPECT at ESAFORM 2020

From 4 to 6 May 2020, the ESAFORM Conference was organised for the first time as on-line conference. In its frame, the ASPECT consortium held a mini-symposium “Tribology in Sheet

Conference on Material Forming ESAFORM 2020

The 23rd International Conference on Material Forming ESAFORM 2020 will take place virtually on 4th-6th May 2020