During the annual Meeting Materials conference of 5 April, organized by M2i, Grade2XL held its second open Additive Manufacturing Design Contest for young engineers. Normally the Meeting Materials conference takes place in December, but due to COVID-19 the December 2021 conference was postponed until April 2022. For the Grade2XL contest we challenged young professionals and researchers to design a novel, multi-material product that can be printed with wire arc additive manufacturing (WAAM). The expert jury had a tough job judging all the designs that were submitted, The winning team will see their idea being realized.

During the live award ceremony the chair of the jury, Marcel Hermans (Associate Professor at Delft University of Technology) and co-chair Constantinos Goulas (Assistant Professor at University of Twente) announced the winning team. One of the team members, Hossein Mokhtarian of Tampere University, was present at the conference to receive the award. Hossein expressed his gratitude to the jury and gave a short presentation about the design. They are looking forward to see their idea printed by RAMLAB.

The winning Design

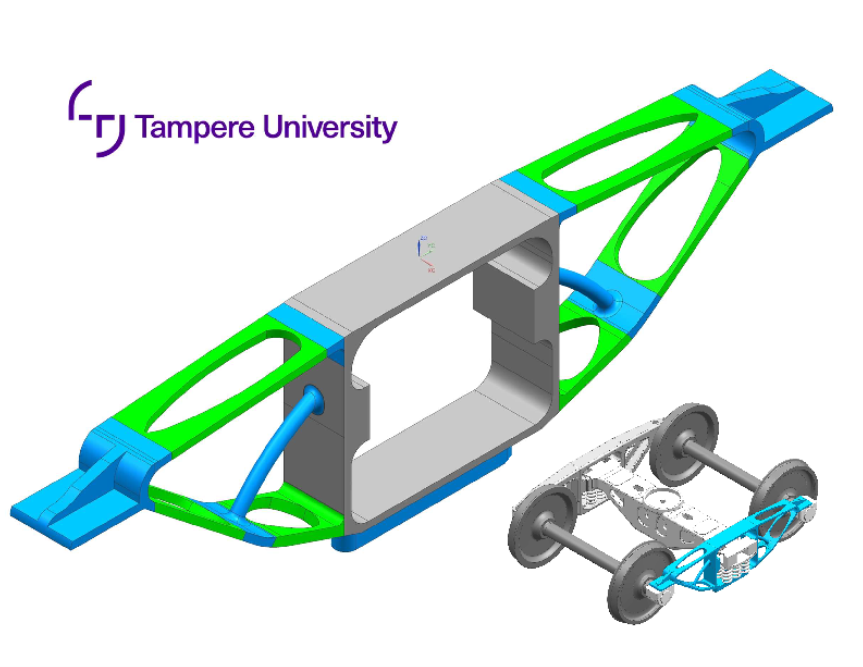

Multi-material topologically optimized bogie for a rail-car application:

Parts with an increased stiffness-to-weight ratio make WAAM-process more competitive, and higher deposition rates positively impact WAAM business cases. This demonstrator is a multi-material topologically optimized structural bogie part for a railway train application. The rationale is to combine high and low strength steel and topology optimization to reduce weight hence costs of bogie production to increase the system’s reparability and life. Final business cases require the price to remain low, which becomes challenging. The material selection combines high strength steel on stressed areas while keeping a low-cost, low carbon steel (everywhere else) as the primary material.

The jury about the winning design

“The integrated approach of setting the design space, the topology optimization, the FE analysis and the tool path planning indicated that a lot of effort was made in this proposal. The main purpose of the design is to reduce the weight of the part, the chosen multi-materials allow this reduction while keeping the original function of the part. This part could have a great impact on the rail industry if it is used on a large scale.”

The winning team

Antoine Queguineur (left) and Hossein Mokhtarian (right) are both working at the Tampere University. Antoine recently decided to start doctoral studies in the field of additive manufacturing at Tampere University. He is interested in the phenomenon affecting the final microstructure of parts manufactured with DED processes and especially WAAM. He has around 10 years of industry experience including 5 years in research and development of additive manufacturing.

Hossein is currently working as a university lecturer and researcher. His research interests lie in the interaction of design and manufacturing technologies and more specifically additive manufacturing. He holds a double Ph.D. degree in mechanical engineering and industrial engineering from a joint-PhD program between Université Grenoble Alpes (UGA, France) and Tampere University (TAU, Finland).

The Design contest will be held every year in December until at least 2024, with submission deadlines mid-November. The next edition will be held on Tuesday 13 December 2022.

Want to stay up to date on all Grade2XL news, subscribe to the newsletter here.