Project Description

Key information

Project in the Spotlight: S17014

Market: Advanced Metals

Written by: Viktoria Savran

Research background

In the automotive industry, the paint appearance of outer panels is strongly influenced by the waviness of the parts after forming. Such waviness may induce diffusive scattering of light after paint baking, which produces a loss of quality of the sheet surface brilliance, specifically with a reduced thickness of the paint coating. As a result, most automotive manufacturers have made strict specifications of the roughness and waviness in the as-received state and after a certain degree of stretching.

There is a huge body of knowledge on crystallographic texture on the macro-scale and the ensuing plastic anisotropy of sheet metals. There are also plenty of literature reports on the orientation distribution on the micro-scale, e.g. literature on the substructure of the deformed state and the consequent nucleation behaviour during recrystallization. However, detailed knowledge of the distribution of crystal orientations on the mesoscale is missing. Some experimental evidence indicates that the orientation distribution on the mesoscale is linked with the waviness increase after stamping, but there is no appropriate parametric description for such mesoscale distributions. There is a strong industrial need to develop such a parametric description, so industries can use this knowledge to optimize the production process aiming to achieve the desired waviness performance.

Research objectives and highlights

The main project aim was to investigate the surface waviness characteristics in cold rolled and galvanised steel sheets after biaxial stretching and correlate it with the mesoscale texture. Further, it was envisaged to perform finite element numerical simulations in order to develop a theoretical understanding of the physical phenomena responsible for varying surface waviness properties of the industrially produced outer car body panels.

The waviness on sheet surfaces was discerned from the measured surface profiles after biaxial stretch deformation. To reveal the root causes of the undesirable waviness in steel sheets, the material microstructure was investigated via optical microscopy, 2D and 3D orientation contrast microscopy through electron backscattered diffraction (EBSD). Numerical modelling was performed using the Abaqus finite element (FE) simulation package with an anisotropic Hill type yield locus. The orientation measurements were performed at scales to cover more than 13,000 grains in 3D volume and ~20,000 grains in wide-field 2D slices. The orientations favouring the presence of peaks in the waviness pattern were thus revealed. Using these observations and certain crystal orientation datasets extracted from the experimental measurements, preliminary FE simulations with different neighbour configurations were performed.

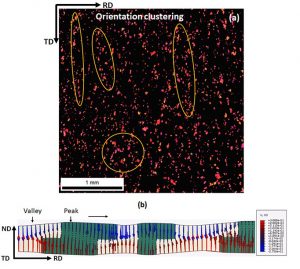

The research has shown that the heterogeneous distribution of the sparsely scattered θ-fibre orientations (<001>//ND) (along with partial α-fibre orientations (<110>//RD)) among the dominant g-fibre component (<111>//ND), plays a crucial role in the appearance of surface waviness. It was observed that the spatial distribution of the minority components, and more precisely the presence of regions that are locally depleted of minority components, is responsible for the observed waviness in the bad performing steel sheets. This can be easily discerned from figure below.

The two types of crystal orientations, i.e. γ-fibre and (θ+α)-fibre grains, were used for FE simulations. A mean field crystal plasticity approach in conjunction with the Hill yield criterion for anisotropic material behaviour described the yielding conditions in the 2D numerical model. When these two types of grains were scattered uniformly, under the equi-biaxial stretch conditions, the (θ+α)-fibre grains thinned 2.5 times more than the γ-fibre grains. Further, a 3D model consisting of different neighbour configurations along rolling and normal sheet directions was implemented, in order to simulate the banding behaviour of similar orientations. A ribbed waviness pattern was predicted in which peaks and valleys formed at the locations of γ and (θ+α) grain colonies, respectively, as shown in figure 1 (b). The research performed in this project provided a clear cut path for future research lines and industrial validation leading to a lasting solution for the deleterious surface waviness in cold rolled and galvanised steel sheets used in outer car body panel applications.

Figure. The cold rolled, annealed and stretch deformed steel sheets show tendency for clustering of preferred orientations – θ-fiber as shown in (a) and partial α-fiber as well. The θ- and partial α-fiber grains lead to the formation of valleys whereas γ-fiber grains form peaks in (b), when numerically simulated using ABAQUS FE in biaxial stretch deformation mode.

Harishchandra Lanjewar (TU Delft)

This research project is one of the very good and crystal clear examples where the influence exerted by the mesoscale microstructure over ensuing plastic deformation and resulting surface characteristics in sheet material is evident. The research outcomes from this project gave a direction to follow in order to find a definite solution for the surface waviness problem in industrially produced flat steel products. I would like to express many thanks to Toegepaste en Technische Wetenshapen (TTW) and M2i for giving me an opportunity to be associated with this project.

Yuguo An (Tata Steel)

As a producer of steel material for body-in-white application, the surface paint appearance of a shiny paint coated steel sheet is for us of crucial importance. From everyday practise we knew that the quality of this brilliance may be adversely affected by the plastic forming of car body parts. The obtained fundamental understanding on how grains collectively respond to externally imposed loading significantly helps us in the search for a perfect finished surface.

Already for more than 20 years texture control of Metal Sheet products is in the focus of attention in the research group of Leo Kestens both at UGent and TU-Delft. By combining state-of-the-art experimental tools for texture and microstructural characterization and advanced simulation methods the intricate relationship between material properties, processing and microstructure is investigated. This knowledge is industrially valorised as it contributes to a better understanding on how to improve the thermo-mechanical processing of metal manufacturing.